Diagnostics

1987 - 1995 Porsche 928 Diagnostics

This information is for 1987 to 1995 Porsche 928s. If your Porsche 928 is 1980 - 1986, please contact us directly for diagnostic information. Please send a note to info@electronikrepair.com if you would like a PDF printable version of this and other diagnostic information.

Diagnostics should be only be performed by a trained technician. If you are a do-it-yourselfer, you are responsible for yourself and your Porsche! Do not attempt tests and repairs that you cannot safely complete. This information is provided solely as friendly advice; Electronik Repair, Inc. accepts no responsibility for the outcome of any work done by those reading these webpages. For more detailed step by step instructions, consult the Porsche factory workshop manuals.

Common No-Start Diagnostics for 1987 - 1995 Porsche 928s

Contact us for diagnostic information for earlier 928s

See LH and EZK diagram website pages for pin assignments mentioned below.

a. Check Relays: A relay is an electrical mechanical device that enables high current load switching controlled by a small current signal. The Porsche 928 uses relays to control many of electrical circuits. Many 928 are still operating with their original relays, so failures are common. The main relays for engine start are:

1987-1989 1990 + Power Supply for:

Fuel Pump Relay XX XXVI Fuel Pump and O2 Sensor

EZK Relay XVI XXII LH and EZK control Unit

LH Relay XXV XXV Fuel Injectors

Starter XIV V Starter

[Horn Relay XII XVI Horn]

Note: The horn relay is the same relay type as the LH and fuel pump relay (and starter relay for automatic transmission cars). So if your horn works, the horn relay may be removed from its socket and swapped with these other relays for testing purposes (or in an emergency as a spare). Bridging relay socket position 30 and 87 closes that circuit and removes relay functionality as an issue for testing. To identify the positions for bridging, match the relay pin numbers that are marked on the bottom of the relay to their corresponding position on the relay socket.

b. Testing the engine RPM sensor. The EZK spark control is the system master, if engine rotation signals are not provided to the EZK, spark will not be generated and the EZK will not provide a turn-on signal to the LH Jetronic fuel injection system. (Note: if your engine has spark, this test and the EZK output stage tests are not necessary).

The first test to perform is a resistance test. It is best to start the measurements at the spark control module connector, since the test verifies the complete circuit. You will need to fabricate a test lead to with a blade to plug into the connector. The resistance reading should be between 600 - 1600 Ohms at EZK connector pins 23 (+) and 6 (-). If the test does not yield the desired results, disconnect the engine speed sensor plug to the wiring harness and test at that point.

The RPM sensor input to the EZK is from an inductive RPM sensor. Inductive RPM sensors generate voltage so a VOM can be used for testing the sensor, you would see the needle of an analog voltmeter twitch when set to the AC scale. Use caution if testing at greater RPM than start-crank speeds, the voltage can be much higher.

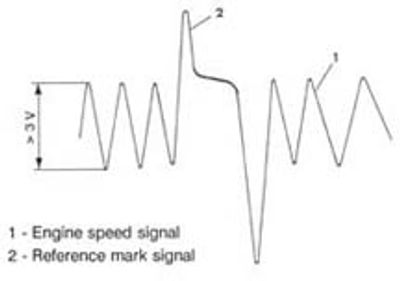

An oscilloscope is needed to verify the pulse shape. As illustrated above, the minimum speed signal (1) voltage is 3.0 V (AC) and Reference Mark Signal (2) output is 5V (AC) when the engine is cranking. EZK pins 23 and 6 are connected to the RPM sensor. EZK pin 24 is the shielded sensor cable.

c Testing the EZK spark module RPM Output: The EZK module provides the signal to turn on the LH fuel injection module; it is the circuit from EZK connector pin 13 to LH connector Pin 1. Check for circuit continuity, if the wire is broken or the connection isn't clean, the car will not start.

The waveform above is what the EZK pin 13 output is a square wave 7 volts minimum.

d. Testing the fuel pump circuit: The circuit from LH Pin 20 goes to the Fuel Pump Relay pin 85, check for continuity between these two points. From the Fuel Pump Relay pin 87 the circuit passes through fuse 42 then to the fuel pump motor. Pull the fuse, check the fuse, and clean the connectors. Check the continuity of this path. Bridge Fuel Pump Relay socket points 30 and 87; the fuel pump should run. If the pump does not run, check for battery voltage at the "+" terminal of the fuel pump and check for a good connection from the "-" terminal to ground.

e. Check for Voltage to Relays: There should be 12V (nominal battery voltage) at the fuel pump, EZK and LH relay pins 30 at all times. This same circuit connects to LH connector Pin 4, check for 12V there too. If there is no voltage, check the + battery connector, which is the point where this circuit begins.

f. LH to Relay connection test: The LH relay pin 85 connects to LH connector pin 21, check for continuity between these two points.

g. Testing the circuit to fuel injectors: The LH connector pin 18 connects to all the fuel injectors. The LH controller functions as the switch from the fuel injector to ground. With the LH relay jumpered between pins 30 and 87, there should be 12 V at LH connector pin 18.

[Model Year 1989 and newer 928s have a spark monitoring system, consult the wiring schematics and workshop manuals for specifics].

When the engine is cranking, an oscilloscope should show the fuel injection pulse. The 12V falls to 0V for a brief moment. Next a brief spike over 12V and the voltage settles back to 12V. The period ti is a function of the on time of the fuel injector as initiated by the LH fuel injection controller.

h. Test EZK Output Stage Control Signal. The EZK unit sends a signal to the spark output stage control modules, which are located in the front of the 928 just behind the bumper on the right side (as you face toward the engine compartment with the hood open). Remove the cover and inspect the two connections, they should be clean and free of corrosion.

Connect an oscilloscope positive test lead to pin 5 and the negative test lead to pin 2 of the disconnected output stage plug. When the engine is cranked, the signal should look like a square wave. If no signal is observed, check the continuity of EZK connector pins 15 and 32 to their respective spark output stage connector pin 5. If there is continuity, the EZK unit may be faulty.

i. What else could it be? If all of these items check out OK, and the fuel pump is functioning, then potential problems could be the system fuel pressure is too low; fuel filter or pipes are restricted, fuel injectors are not functioning correctly, or .... the LH Jetronic fuel injection module is not functioning correctly and requires a rebuild.

Electronik Repair, Inc. is not affiliated with Porsche AG, Saab, Volvo, or Robert Bosch GmbH. All brands and marks are property of their respective owners.

Copyright 2020. Electronik Repair, Inc. All rights reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.